From your idea to success: We Design, We Manufacture, We Innovate

Contact us

- C. Brújula, 4, PISA, 41927 Mairena del Aljarafe, Sevilla

- +34 955 320 750 / +34 609 536 676

- info@creafab3d.com

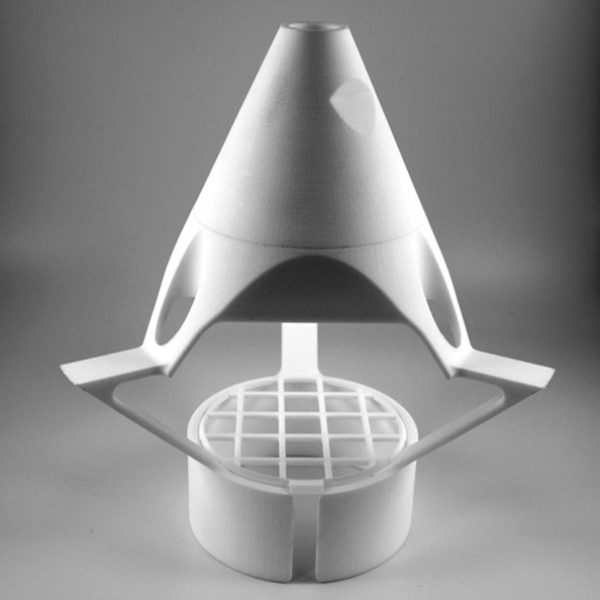

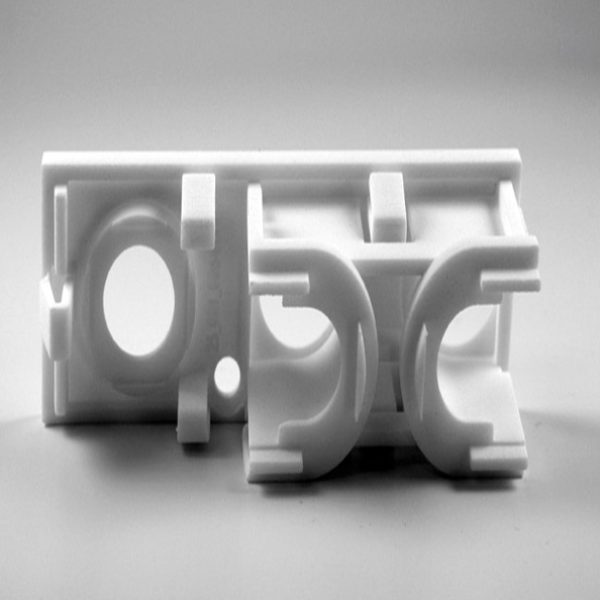

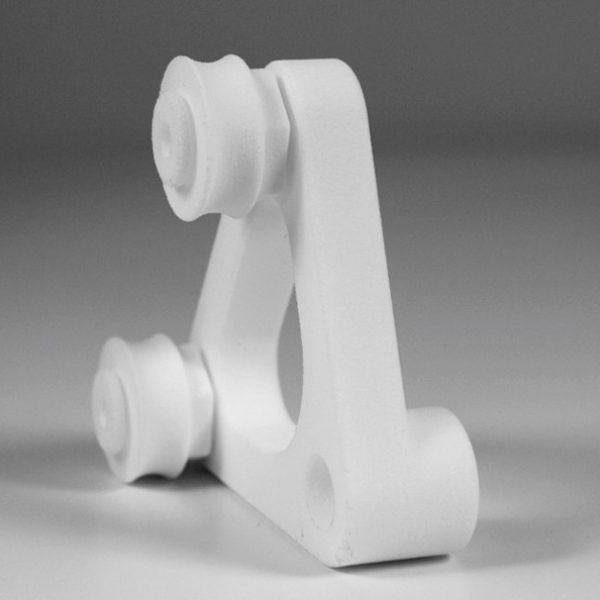

Selective Laser Sintering (SLS), also known as Selective Laser Sintering, represents a state-of-the-art additive manufacturing technology for 3D printing with high-quality plastics. Through our advanced SLS additive manufacturing machines, we transform data from CAD models into plastic components that stand out for their rigidity and strength.

This innovative additive manufacturing process is specially designed for the production of polymer components for final parts and prototypes. SLS is one of the most widely used and reliable 3D printing techniques for small and medium scale manufacturing of end-use industrial plastic components.

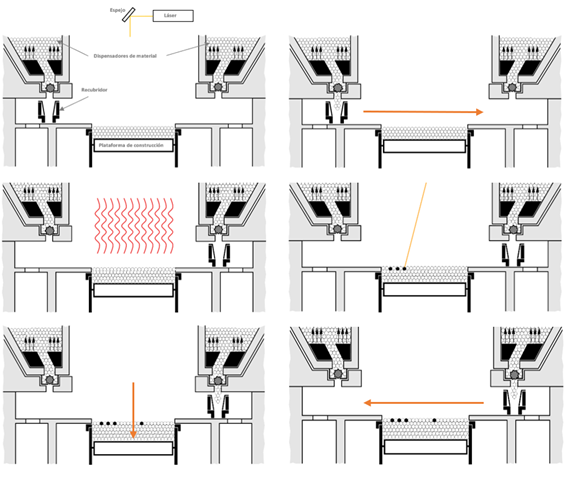

SLS systems use a laser as an energy source to achieve selective melting of plastic material in powder form, a process that involves the precise melting and solidification of particles. This method falls into the category of Powder Bed Fusion processes and stands out as one of the most advanced and reliable technologies in the field of additive manufacturing.

First, a homogeneous layer of material is distributed and then preheated. Using 3D data derived from a CAD model, our laser system accurately melts the plastic material in predefined areas on the powder bed, located on the system’s build platform. After each melting phase, the platform is lowered and a new layer of powder is introduced, repeating this build process layer by layer until the final part is obtained.

Unlike other 3D printing methods, such as stereolithography (SLA) and fused deposition modeling (FDM), SLS dispenses with the need for additional supports, as the surrounding powder itself acts as a support throughout the process. Rely on us to reach new standards of precision in additive manufacturing.

Discover on our platform a variety of advanced polymeric materials designed for Additive Manufacturing in SLS. Nylon, especially PA 11 and PA 12, stands out for its lightness, strength and versatility. We offer flexible options such as TPU and high temperature materials such as PAEK. Trust us to find the perfect material that will elevate the quality and durability of your SLS Additive Manufacturing projects. In your quest for excellence in SLS Additive Manufacturing, trust our platform to provide you with access to high quality materials that elevate your projects to new levels of performance and durability.