DMLS

Direct metal laser sintering

What is DMLS technology?

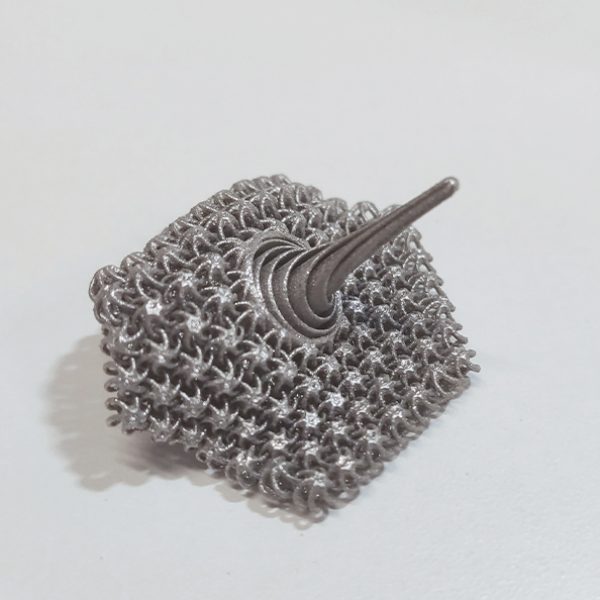

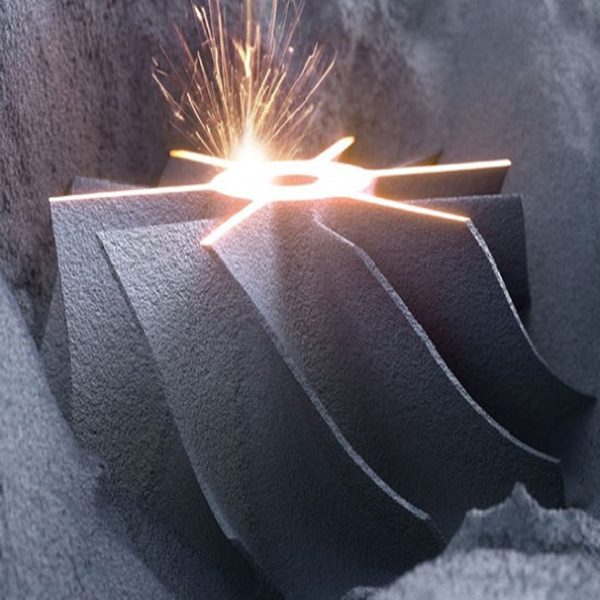

DMLS (Direct Metal Laser Sintering) technology represents a milestone in additive manufacturing by Powder Bed Fusion, consolidating itself as one of the most advanced and reliable processes in the field of additive metal manufacturing worldwide.

This innovative approach stands out for its application in the production of high precision metal components, being a preferred option in diverse sectors such as aerospace, automotive, medical, defense, energy, as well as tools and machinery. The versatility of DMLS technology ensures excellent results, positioning it as a fundamental pillar in the manufacture of industrial metal components.

¿Cómo funciona el proceso DMLS?

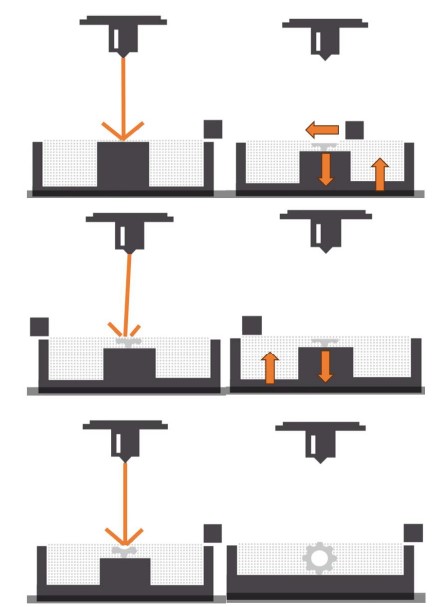

With DMLS technology, the production of metal parts reaches an exceptional level of precision directly from CAD models, using a metal alloy in powder form. During this advanced process, an ultra-thin layer of metal powder is evenly distributed on the build platform. Subsequently, a powerful and precise laser melts the material exactly at the points defined by the CAD model, solidifying the particles to the desired shape. This process is repeated for each layer until the final part, with a density close to 100%, is complete. Finally, the part is separated from the build platform and, if supports are present, they are removed.

These key steps precisely define the DMLS process:

- Uniform distribution of the powdered metal material on the build platform.

- Precise laser melting to shape the desired layer.

- Lowering of the platform to allow for the thickness of the next layer.

- Re-distribution of powder to form the next layer.

- Meticulous repetition of the process layer by layer until the part is completely formed.

part.

¿De qué materiales disponemos para DMLS?

Our technology features an extensive range of high-performance technical materials, meticulously engineered and optimized for the additive manufacturing process. Depending on the specific needs and requirements of each application, we can create products using aluminum alloys, cobalt-chromium, refractory metals, stainless steels, tool steels and titanium, as well as precious metals such as gold. This range of options ensures that each project is made with the most suitable materials to achieve optimum levels of performance and durability.

From your idea to success: We Design, We Manufacture, We Innovate

Contact us

- C. Brújula, 4, PISA, 41927 Mairena del Aljarafe, Sevilla

- +34 955 320 750 / +34 609 536 676

- info@creafab3d.com